The five most common ground mounting solutions for solar systems: C-posts, screw anchors, ground screws, concrete pillars, and ballast. It all depends on the nature of the ground beneath your feet.

C post

Roll molded C-posts are a common component throughout construction, they are also the most common ground mount option for solar systems. C-posts, I-beams, or H-beams are installed with a ram driving them directly into the ground. Shelves are then attached to the exposed beam. Beams can be installed in clay, black, and sandy soils and work best when the site is free of rocks. Ground friction holds the stakes in place. For C-posts in sandy soil, the anchoring depth depends on the grain size. Higher water tables can reduce friction and require the pile to be driven deeper than normal. It can work in any soil condition and depends only on the mechanical properties of that soil for friction how deep the pile needs to go. Determining the correct depth requires a stake test, a process that can be expensive. that money by installing more poles, so pole-mounted solar doesn’t make sense for small projects. C-posts are more expensive than other smaller post mounts but are ideal for larger scales because they are very strong and require fewer leg installations per rack compared to coiled anchors or ground screws.

Helical Piles

Screw piles are cylindrical posts with, as the name suggests, a two-or-more-inch-wide helix mounted or attached near the bottom of the post. a cone of land on top. Spiral piles are installed by digging an initial pilot hole and using a skid steer loader with a rotating attachment to rotate the assembly in place. With a smaller surface area, the spiral piles are embedded with minimal soil disturbance. The design of the spiral piles makes them ideal for sandy, black or loamy soils as well as areas with high water tables where the piles require greater embedment depths. Spiral piles are embedded at shorter depths in soft, sandy soils compared to C-posts. Other foundations may not work, but the flanged spiral works perfectly for these…as a driven pile in almost all locations is going to have very different characteristics by comparison to a spiral [which] has almost identical properties at every point.

Ground Screws

Ground screws work similarly to spiral piles and also create a cone of earth that resists upward loading. The difference in the design of the ground screw is its threaded end, which leads to a point, similar to carpenter screws. We manufacture ground screws of different sizes to suit different soil types. To install a ground screw in dense soil, contractors drill a pilot hole, drive the screw in, and use a rotary hydraulic drive to drive the bracket into the ground. In a medium to loosen density soil, ground screws can be driven directly into the ground. These mounts were built to work in rocky landscapes. The pointed threaded end features a forged chisel point that can push smaller rocks aside, and installers can even drill a starting hole in larger rocks to drive the ground screw right into the ledge. Ground crews work in a variety of soils and it comes down to how you design the ground screw to fit where you are trying to install it. On a looser site, you might have a longer or wider ground screw than on a rocky side? We can take these different ground conditions into account with the construction of the grounding screw. This mounting solution has a smaller post surface area similar to spiral piles but is available in long post lengths to ensure proper embedment depth. A set of stands can be attached to grounding screws of different lengths, keeping the panels level while conforming to different topographies.

Ballasts

Ballast systems are a non-penetrating foundation solution for solar energy. Shelves attach directly to a base, block, or basket, and concrete is commonly used as a weight to hold it in place. to the square; or concrete is poured into containers and cured in place around the posts. The decision as to which specific solution to use depends on site conditions, labor costs, and the size of the facility. be penetrated because of possible contamination. The cast-in-place solution is ideal for projects with low labor costs and easy access to heavy equipment. The job site must be able to handle the weight of a concrete truck and requires the handling of concrete pouring hoses. nearby projects that can supply the concrete blocks. Due to their modular structure, they are easy to deliver. Installers can remove the blocks from the trailer and place them in place before connecting the shelving systems. The use of above-ground concrete foundations means panels can be dismantled and racks moved, for example in landfills where routine inspections need to be carried out. Using heavy equipment on volatile job sites means choosing machines that use tracks instead of tires. A tracked machine’s weight spreads more evenly over the soil’s surface than wheels, Freshwater said, relieving soil pressure in sensitive locations.

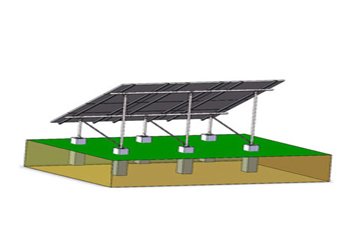

Concrete Piers

There is another method of attachment that uses concrete but requires significantly more excavation than narrower foundations with piles: concrete piers. These posts are hung in holes 12 to 18 inches in diameter and 6 to 8 feet deep, and concrete piers are suitable for smaller projects, sites with corrosive or swampy soils, and installations in regions prone to hurricanes and high winds. They tend to be more expensive than the smaller drilled or driven mounts. It’s on a 30, 40% incline where you can’t get standard construction equipment locally or the construction equipment you can use is limited. At other times, when we’re running projects that are highly hurricane-prone, clients tend to play it safe and choose a more solid foundation. Concrete posts are often the only option in high pH soils where corrosive soils will damage metal posts. fall apart so quickly. Things other than acidity or pH are soil sulfides, chlorides, soil resistivity, and moisture content. So, if you have very corrosive floors, concrete is an option to help you achieve the system life you desire. Whether the ground is sandy, rocky, loose, dense, or corrosive, there is a market for solar mounting products designed to meet the needs of an installer on most job sites. Our mounting system is suitable for all common floors. Floor shelving systems come with high pre-assembly for on-site use with a low installation cost. We look forward to hearing from you. Email us and we’ll get back to you if you have any questions about our products.